Home

Tutorial's

Image collection

Calculator

Projects

MCQ's

3d Models

Invention Hub

How it works

Download Our app

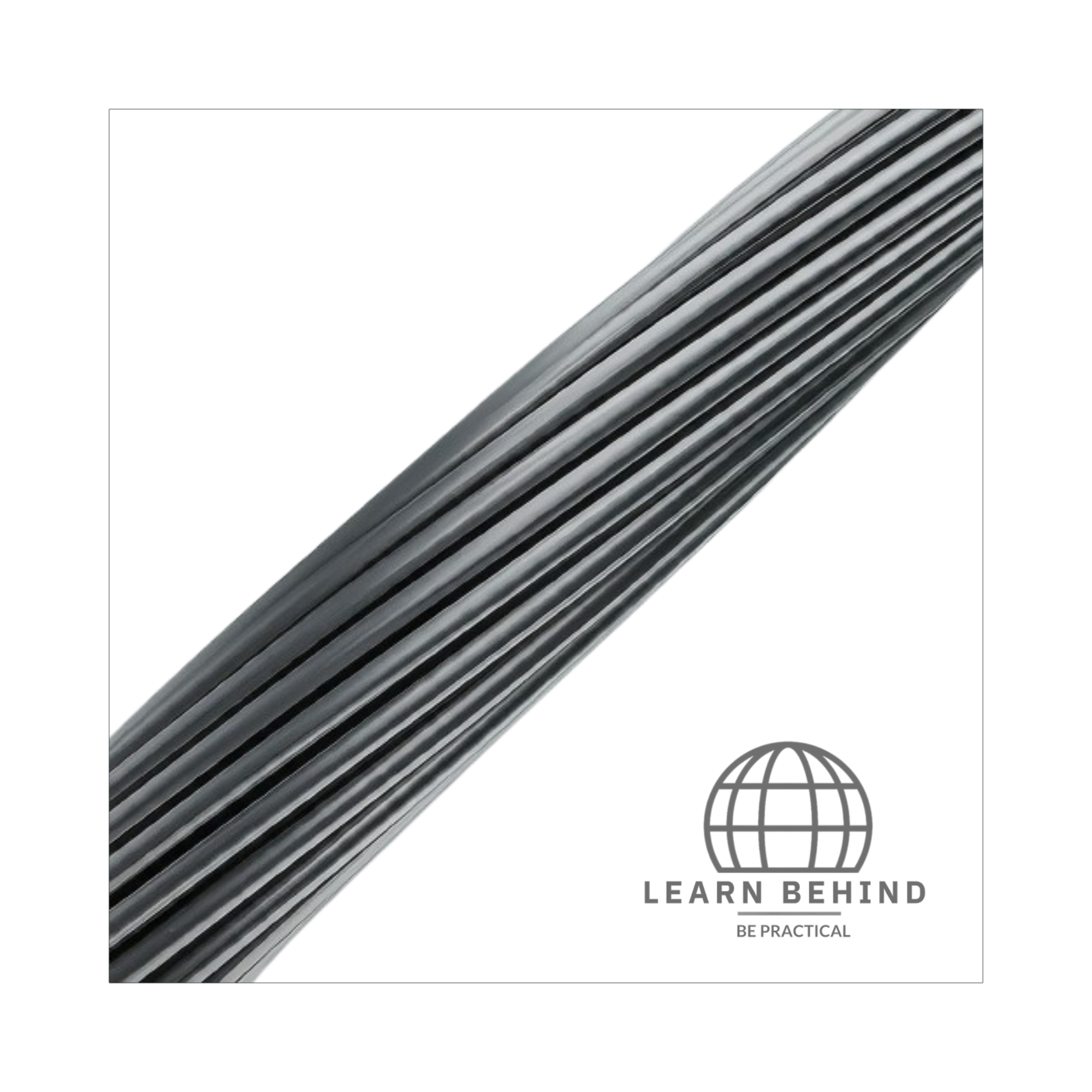

Module 29: ACSR (Aluminum conductor steel reinforced) conductors

Manufacturing of ACSR is carefully done to ensure that the final product meets specifications in terms of its strength and conductivity. Production starts with the production of a steel core, which is from high-strength steel wires. Such wires are drawn to the required diameter and then twisted together into a solid core. This core provides the mechanical strength necessary for the support of the conductor under tension and environmental stresses.

The next stage is the preparing and drawing of aluminum wires at appropriate thickness. These are then helically wound around the steel core in one or more layers. The principle of winding has to be such that the conductor has consistent and uniform characteristics with regard to the distribution of both aluminum and steel. The final stage of manufacture consists of several quality control tests, which are meant to determine the mechanical and electrical properties of the conductor before it is shipped for use.

Difference Between Normal Aluminum Conductor and ACSR

1.Composition:

Normal Aluminum Conductor: Composed only of aluminum. It is light, with good electrical conductivity, but without the necessary mechanical strength to bear long spans or high tension.

ACSR (Aluminum Conductor Steel Reinforced): It includes one central steel core with a number of aluminum strands laid around it. The core of steel gives high tensile strength, while layers of aluminum offer high electrical conductivity.

2.Strength:

Normal Aluminum Conductor: It has limited tensile strength and may be suitable only for shorter spans or lower load conditions. It sags more under heavy load conditions or environmental stress.

ACSR: Due to the strong steel core inside, this conductor, with high mechanical loads and long spans within reach, resists sagging or deformation better under extreme conditions.

3.Conductivity:

Normal Aluminum Conductor: It would provide good electrical conductivity, which is perfect for efficient power transmission. Often, pure aluminum conductors are used in places where electrical efficiency is the main concern.

ACSR: It also provides high conductivity due to the use of aluminum strands. However, its main advantage is that it can bear heavy loads while remaining conductive.

4.Applications:

Pure Aluminum Conductor: It finds most applications only in low voltage and less demanding mechanical requirements. It is commonly seen on short-distance distribution lines or where the dominating factors are weight and cost.

ACSR: It is more functional in high voltage transmission lines and for a long distance of power delivery. Its strength and durability allow it to become overhead power transmission cables over long distances, withstanding severe weather conditions.

Properties of Aluminum Conductor Steel Reinforced (ACSR) Conductors

Strength: The steel core of ACSR conductors imparts great tensile strength to these conductors and enables them to bear very heavy loads and span over very long distances with not too much sagging. Thus, ACSR conductors are ideal in high-tension applications and for very-long-span overhead power lines.

Conductivity: The outer layer of aluminum in ACSR conductors provides very good electrical conductivity. This reduces the energy losses while transmitting power. Aluminum has low electrical resistance that permits the flow of electricity with minimum loss over a long distance.

Corrosion Resistance: The corrosion of the aluminum strands is resisted by a thin, protective oxide layer that forms. The steel core is normally treated or coated to make it withstand corrosion.

Weather Resistance: ACSR conductors are designed in order to stand varying extreme weather conditions such as high winds, heavy ice, and extreme temperatures.

Weight: Even though the ACSR conductors are heavier than the single pure aluminum conductors, they still tend to be lighter when compared to pure steel conductors of similar strengths. This makes handling and installation easier with regard to retaining strength.

Flexibility: The several strands of aluminum give some flexibility to the conductors by allowing them to bend in installations and be adjusted. The flexibility also helps in adjustment to variable environmental and structural changes.

Tensile Strength: Manufacturing ACSR conductors combines the mechanical strength of both aluminum and steel, hence they can withstand very high mechanical loads due to strong winds and ice loading. Such structural integrity imparts tensile strength in them, along with minimum loss of their constriction.

Thermal Properties: ACSR conductors possess thermal expansion properties owing to the material-aluminum. Thus, they show expansion and contraction according to rising and falling temperatures, which must be provided during installation to prevent excessive sag or stress in conductors.

Costs and Economics: Although the prices are far higher than for conductors made of pure aluminum or copper, the strength and efficiency of ACSR usually justify the cost in very long-distance and high-tension applications.

Impedance: The ACSR construction has low impedance, which is ideal to avoid voltage drops and to maintain efficiency in the power transmission. Because of its design, long spans do not affect electrical performance.

Applications of ASCR:

Transmission Lines: ACSR conductors apply to high voltage power transmission lines. They are good carriers of heavy electrical loads withstood by mechanical stresses; hence, they are fit for very long-distance transmission of electricity from the power plants to sub-stations.

Long Spans: The ACSR conductors are suitable for very long spans between utility poles or towers since they have a high tensile strength. They reduce sagging and maintain a steady supply of electricity over large areas.

ACSR conductors find their application in overhead power lines requiring high tension. The strength that enables the ACSR conductor to bear environmental stresses such as high wind and ice loading on the conductors is very considerable.

Distribution Networks: ACSR conductors also find their application in urban and rural power distribution networks. They reliably meet the challenge of effective electricity distribution from the substations down to the end-users, accompanying mechanical and electrical demands.

Industrial Plants: ACSR conductors find their application in the electrical system of various industrial plants and commercials that require solid and dependable transmission of electricity. They support huge power loads that are needed in different industrial operations.

Remote Locations: ACSR conductors are used for their strength in such areas and conditions. They are put in place around areas of rough topography and those who possess detrimental environmental conditions that would make other conductors non-viable.

An upgrade to infrastructure: ACSR is generally utilized to upgrade outdated overhead transmission lines. They may replace the old conductors in the transmission lines for higher capacity, increased reliability, and to meet modern demands in electricity.

Lines Strengthening: ACSR conductors can be added in the existing power lines for reinforcement, either due to an increased load or harsh environmental conditions that impact the power line system's total strength and performance.

Applications in Railway Electrification: The ACSR conductors can be used in the electrification of high-speed railway systems. These are foreseen to be used for the transmission of power that is required to supply electric trains running over a long distance with efficiency.

Related articles

- ACSR (Aluminum conductor steel reinforced) conductors

- Properties and Applications of Copper

- Properties and applications of aluminum

- Joules Law of electric heating

- Classification of Materials based on Resistivity

- What is voltage ?

- What is Power?

Related Calculator

- Resistivity Calculator

- Resistance Calculator

- Heat Calculator

- Voltage Calculator

- Current Calculator

- Series Capacitor Calculators

- Parallel Capacitor Calculator

Related Inventions